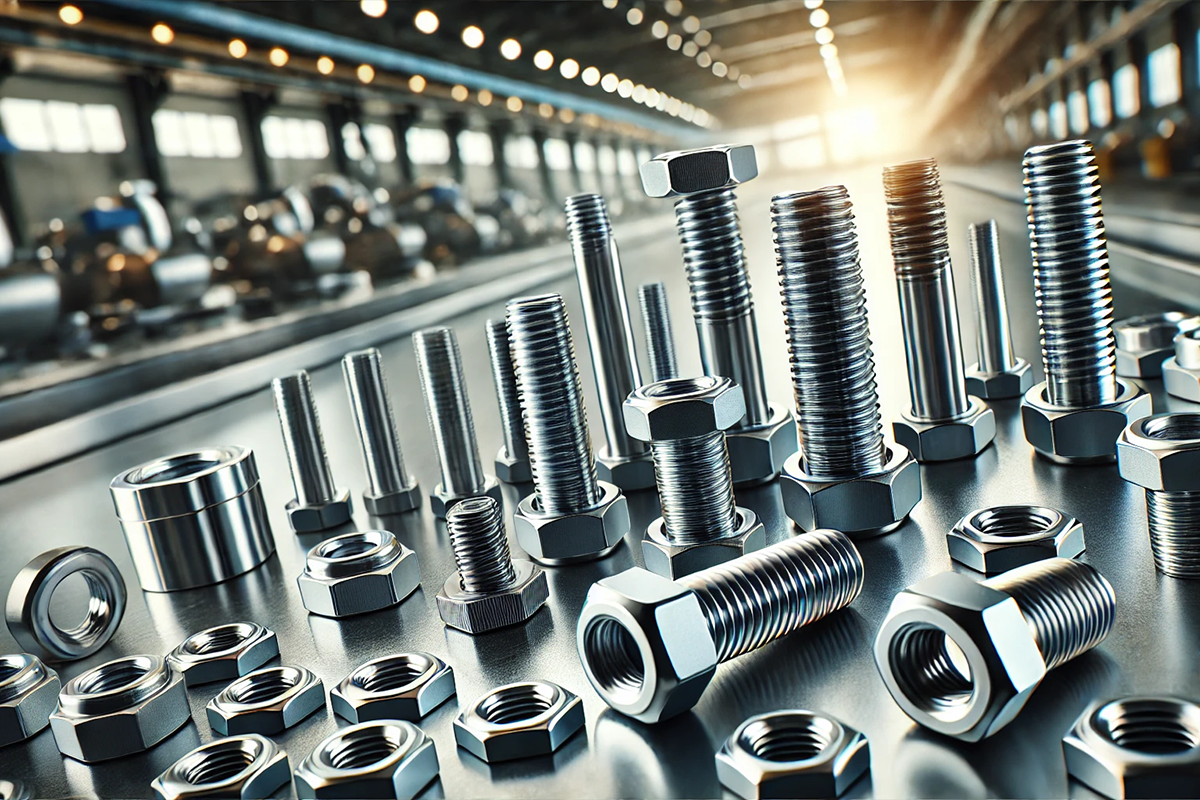

What Is a Special Bolt? How to Order a Special Bolt?

Every structure has a connection point: machines, steel

constructions, pipelines... If they're holding together, there is surely a bolt

in between. But not every bolt fits every purpose. Standard dimensions

may not be enough, or sometimes the conditions are so challenging that a unique

solution is required. This is where special bolts come into play.

Sometimes they must withstand high temperatures or corrosive chemicals;

sometimes they must be mounted without damaging sensitive surfaces, or

tightened in a way that they will never be removed. A special bolt is

not just a fastener—it’s an engineered solution tailored to a specific need.

What Are Special Bolts?

Bolts produced in standard sizes and specifications may offer sufficient

solutions for general applications, but they often fail to meet the needs of

more complex projects. At this point, special bolts become essential. Special

bolt types are fasteners designed with specific materials, dimensions,

thread structures, or coatings to meet the technical requirements of a

particular application or system. These products exceed standard options in

terms of both strength and durability.

Shaped by R&D efforts, prototype testing, and field

applications, these bolts require direct communication with the customer during

the production process. Because every special bolt is essentially an

engineering solution to a specific problem.

Types of Special Bolts

When we talk about special bolts, it's not only about size differences.

These bolts can be produced in a wide variety of combinations to be used in

high temperatures, corrosive environments, high-pressure, or vibrating systems.

Special bolts made from stainless steel are preferred in industries

requiring chemical resistance; whereas high-strength steel bolts with grade

8.8, 10.9, or 12.9 are used in heavy machinery or large steel constructions.

They can be designed with or without threads, with flanges,

paired with nuts, and with internal or external torque applications—these are

common features in special bolt types. Surface coatings also vary based

on the application area; electro-galvanized, hot-dip galvanized, zinc-nickel,

or PTFE coatings are used to increase resistance to environmental conditions.

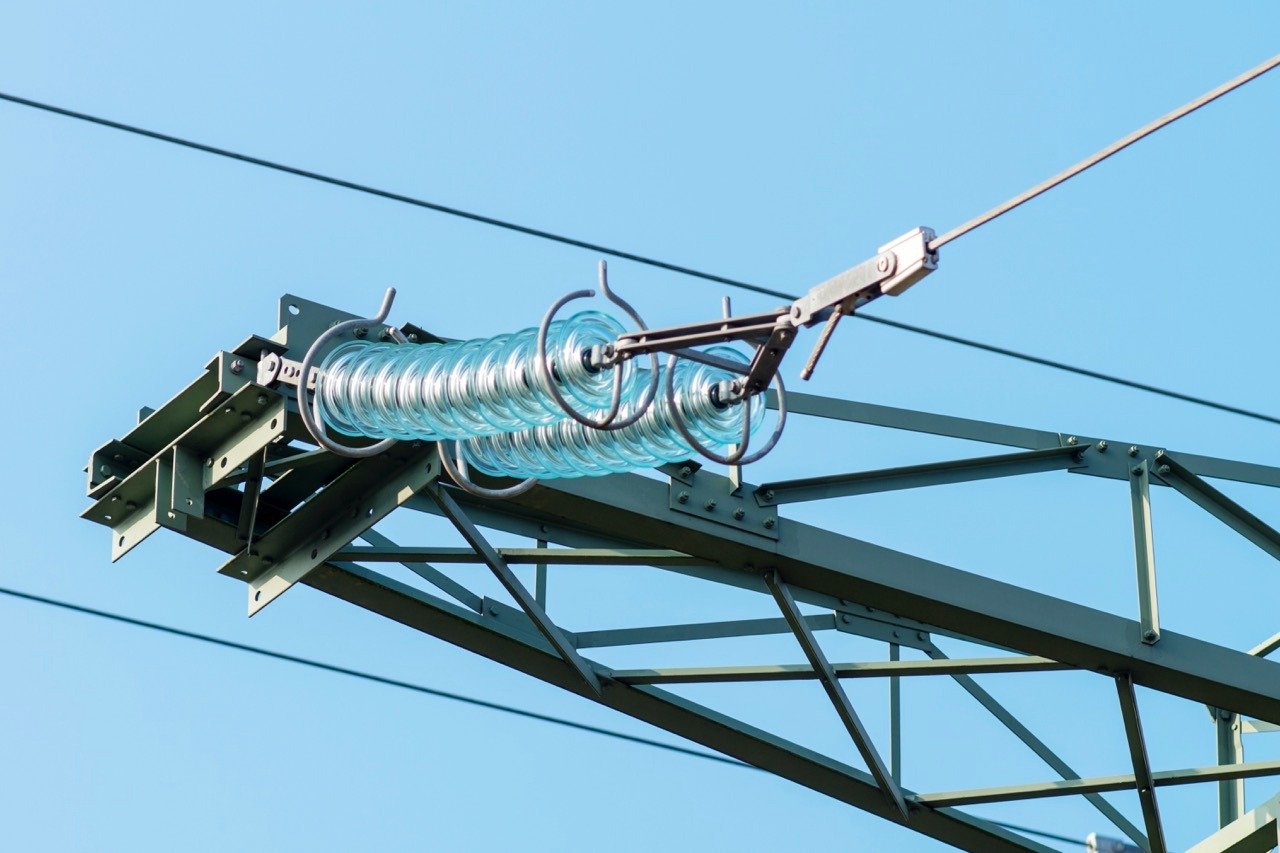

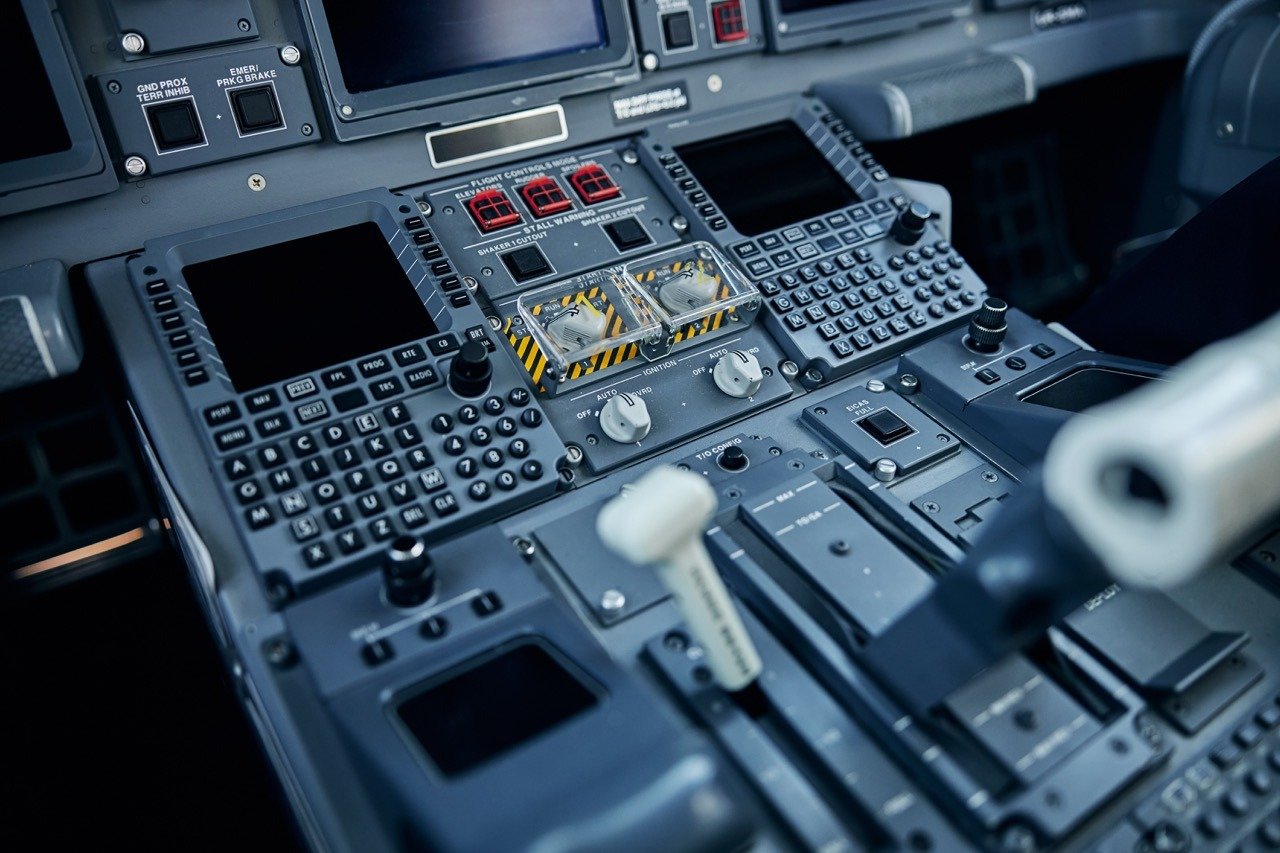

Where Are Special Bolts Used?

Special bolts are indispensable especially in situations where standard

parts cannot offer solutions. Rail system projects, dams and hydroelectric

power plants, wind turbines, steel structures, automotive production lines,

defense industry applications, and custom machinery manufacturing are among the

most common areas of use.

In these projects, criteria like installation precision, load-bearing capacity, and long lifespan are critical—hence non-standard bolts are preferred. Additionally, in some projects, welding or machining cannot be performed on-site; in such scenarios, pre-manufactured special bolts save time and improve safety.

In these projects, criteria like installation precision, load-bearing capacity, and long lifespan are critical—hence non-standard bolts are preferred. Additionally, in some projects, welding or machining cannot be performed on-site; in such scenarios, pre-manufactured special bolts save time and improve safety.

What to Consider When Choosing a Bolt

Choosing the right bolt is essential for safety, durability, and

functionality of the connection. Incorrect material selection may cause serious

corrosion problems; an inappropriate strength class could lead to deformation

or breakage at the joint. When manufacturing special bolts, the

technical details of the application area must be fully shared.

Load direction, application temperature, chemical

environment, surface conditions of the joint, torque data, and ease of assembly

are all factors that directly affect the production process. Especially in

high-precision applications, producing and testing a sample in advance ensures

the final product quality.

What Affects Special Bolt Prices?

Unlike standard products, special bolt prices depend on

many technical details. First, the type of raw material has the greatest

impact. Stainless steel, high-strength alloys, or specially coated metals

directly influence the price. Second, production quantity matters. The higher

the quantity, the lower the unit cost; however, small batch production requires

special workmanship and can be more expensive. The third important factor is

production complexity.

Requests such as complex geometries, tight tolerances, or

multi-stage thread structures prolong production time and increase cost.

Additionally, quality control tests—such as ultrasonic testing, magnetic

particle testing, and tensile or fracture testing—are also factored into special

bolt prices. Finally, delivery time can also influence cost. Urgent

production leads to schedule pressure and is reflected in the pricing.

How to Place a Custom Bolt Order?

When there is a need for a custom bolt, the ordering process must be handled much more carefully and based on precise information compared to standard product purchases. This is because what’s being ordered is not just a product, but a tailored solution. The first step is to clearly define the technical details of the application area. What material will the bolt be fastened to? What is the load direction? Are there any challenges such as humidity, chemicals, high temperatures, or vibrations in the environment? These factors influence every aspect of the bolt—from the material and surface coating to the thread type and tolerances.

Simply saying “I need a custom bolt” is not sufficient when contacting the manufacturer. A request supported with technical drawings or precise measurements ensures the correct product is manufactured and prevents loss of time. If no drawing is available, then the details should be described as clearly as possible: diameter, length, thread type and direction, head shape, whether a nut is needed, hardness grade if necessary, and type of coating—all technical specifications should be shared. If it's possible to provide a photo or a sample from the application area, it will significantly assist the manufacturer.

The second important point is the quantity of production. While some custom bolts are produced as one-off solutions, some projects may require thousands of pieces. This information is crucial for pricing and production planning. Delivery time should also be clearly discussed. Although express production might be possible for urgent needs, this can have an impact on cost.

Quality requirements must also be clearly stated during the ordering process. If there are specific certifications required for the products (ISO, EN standards, 3.1 material certificates, mechanical test reports), they should be mentioned from the beginning. Some tests and inspections can only be performed during manufacturing and cannot be retroactively applied.