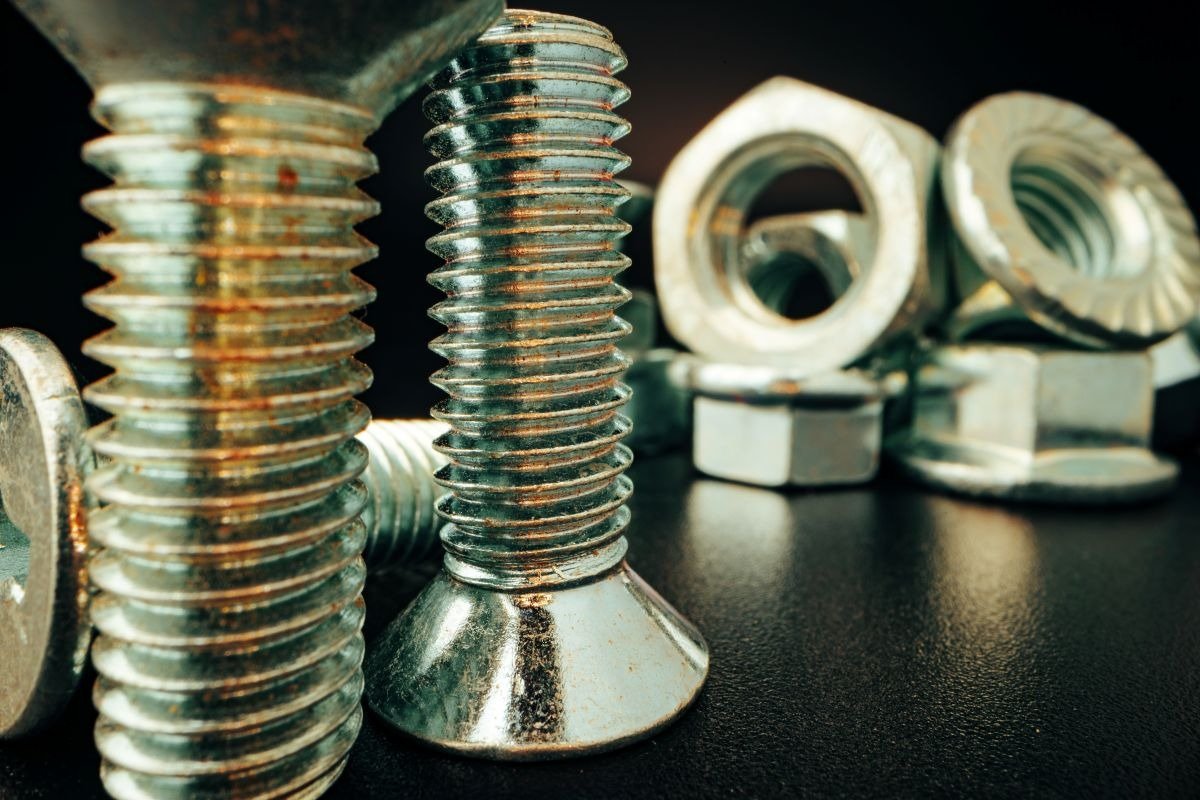

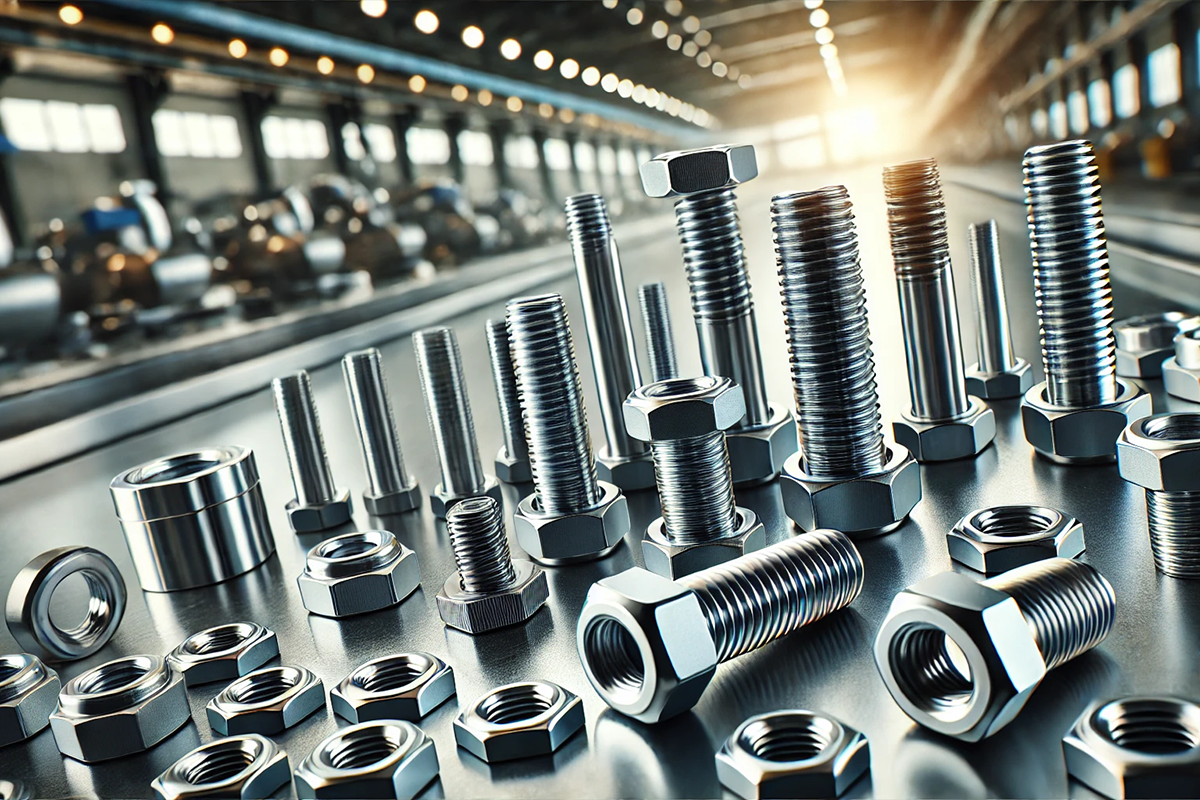

Stainless Steel or Galvanized Bolt? Which Material Is More Suitable?

If you're aiming to build a durable structure or manufacture

a long-lasting machine, it's not just the main components that matter you must

also carefully select the fasteners that hold them together. Hardware like

bolts and screws are often overlooked, yet they directly impact the integrity

of the entire system. Especially in outdoor systems or high-humidity production

lines, the corrosion resistance of fasteners plays a critical role in ensuring

sustainable operations. One of the most common questions technical users face

is: Should you choose stainless steel or galvanized bolts? Is the

difference only in cost, or are there significant differences in performance

and longevity?

Why Is Material Selection for Fasteners Important?

In industrial production, construction, and mechanical

systems, fasteners not only keep components together but also play a decisive

role in the safety and lifespan of the system. That's why the question of

whether to choose stainless steel or galvanized bolts is essential for

technical procurement specialists, civil engineers, and production managers.

While they may appear similar, these two options can yield very different

results in the long run.

Technical Advantages of Stainless Steel Bolts

Stainless steel, thanks to its chromium and nickel

alloys, is naturally resistant to rust. It doesn't require coating—its strength

comes from within. This feature offers a significant advantage in outdoor

applications, high-humidity environments, or facilities exposed to chemical

vapors. Components like stainless screw and stainless screw nut

can operate for years in such conditions without the need for intervention.

No surface deformation, rust bubbling, or seizing occurs,

which means these fasteners can be removed and reused when necessary. In

long-term projects, maintenance processes, and high-risk connection points, stainless

steel bolts make a considerable difference.

What Do Galvanized Bolts Offer And What Don’t They?

Galvanized bolts are produced by applying a zinc coating to

carbon steel. This coating provides temporary corrosion protection. However,

its effect is superficial and limited. Once the coating is scratched or worn

over time, the underlying steel quickly oxidizes. For this reason, galvanized

products are typically used in indoor settings or systems with minimal

environmental exposure.

Their lifespan varies based on coating thickness,

application method, and humidity level in the environment. Periodic

maintenance, connection checks, and timely replacements are required—adding to

operational time and cost burdens.

Is the Lower Price of Galvanized Bolts Worth It in the Short Term?

At first glance, stainless bolt prices may seem

higher than those of galvanized products. However, the comparison shouldn't be

based solely on purchase price. When you factor in issues like unremovable

connections, system damage due to rust, early maintenance needs, or product

replacements, stainless steel products often have a lower total cost of

ownership.

While stainless screw nut sets can operate for

extended periods without maintenance, galvanized products have limited

durability and often require spare parts. This not only affects operational

continuity but also reduces production efficiency.

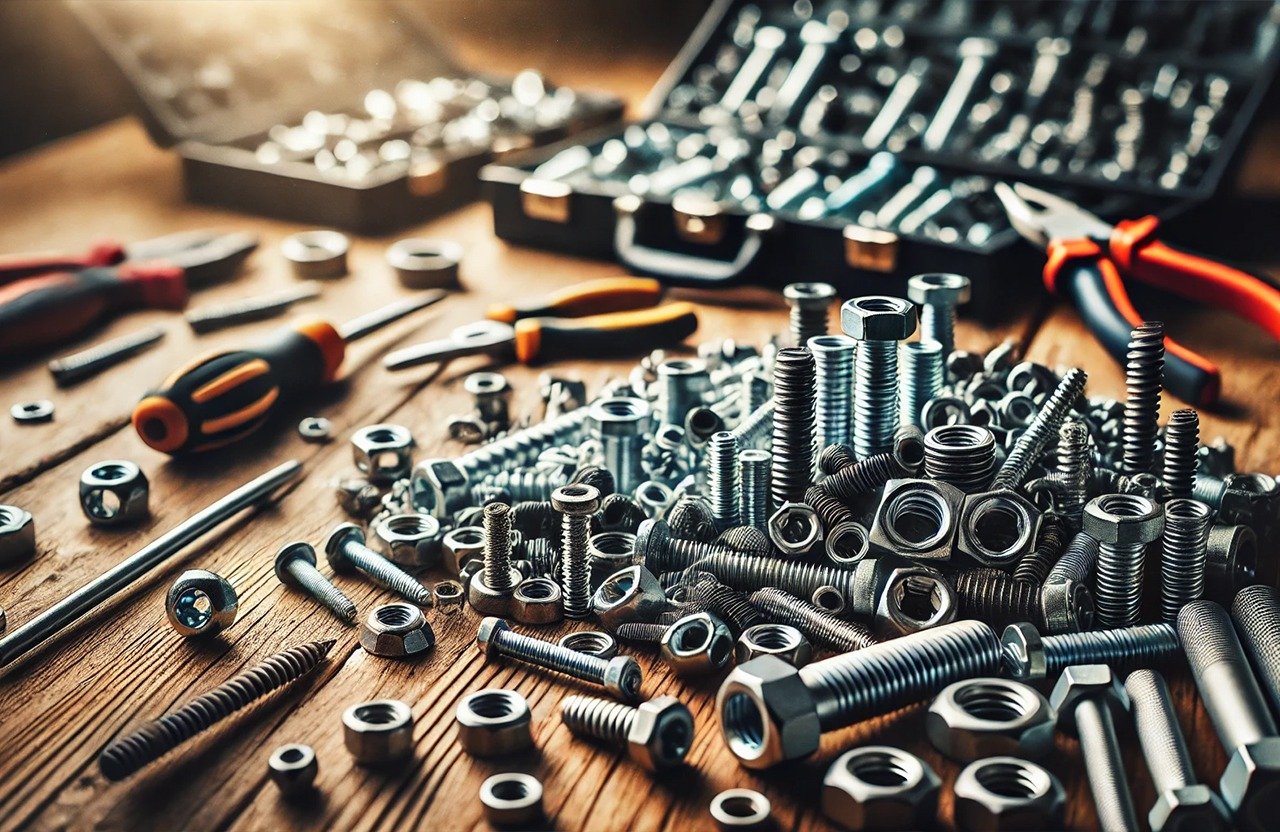

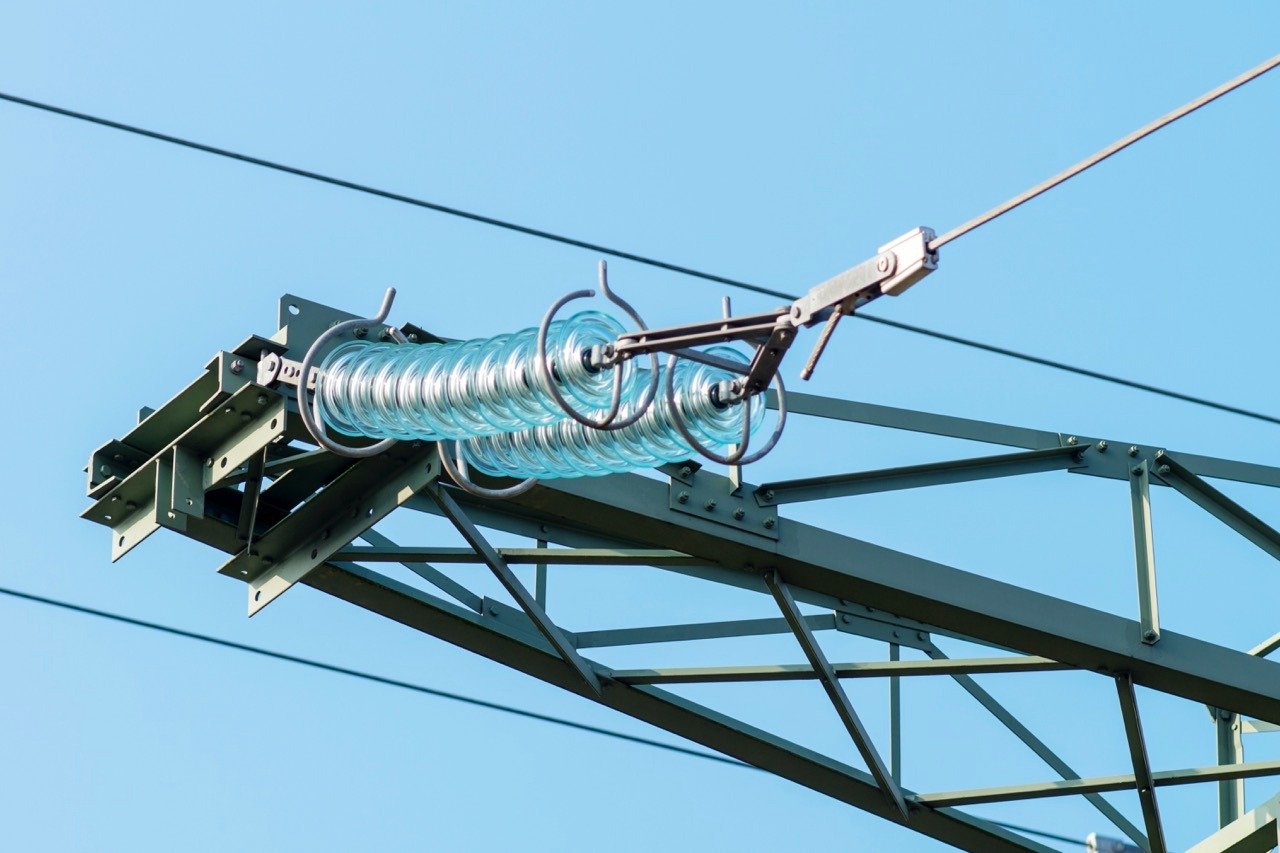

Which Bolt Should Be Used in Which Application?

For outdoor structures, components exposed to water or

chemicals, metal constructions with a high risk of rust, and hygienic

production lines in the food or medical industries, stainless steel

fasteners should be the first choice. In these areas, products like stainless

screw and stainless screw nut are critical for ensuring the system’s

long-term, safe operation.

Conversely, for low-cost and indoor applications, galvanized

bolts may be preferred in short-term solutions or systems that undergo frequent

maintenance. Even in such cases, environmental conditions must be carefully

evaluated before making a decision.

Which Fastener Should You Choose?

Every structure is like a chain and a chain is only as

strong as its weakest link. Fasteners like bolts are critical links in this

chain. Stainless steel, with its technical advantages and long-term cost

efficiency, offers a smart investment across many sectors. Its superior

resistance to corrosion, ease of maintenance, and durability safeguard the

systems at the heart of production.

Although stainless bolt prices might seem like a

budget strain at first, their long service life and reliable performance more

than make up for the initial cost. The correct material choice should be made

by carefully analyzing technical requirements and environmental conditions—ensuring

not just today’s, but also tomorrow’s safety and performance.