What Are the Roof Screw Types and Their Areas of Use?

The most exposed part of a building to external factors is

undoubtedly the roof. Rain, snow, wind, temperature changes... To ensure the

roof remains intact under such harsh conditions, not only the roofing material

but also the fasteners that keep it in place are of critical importance. This

is where the roof screw types come into play.

What Is a Roof Screw?

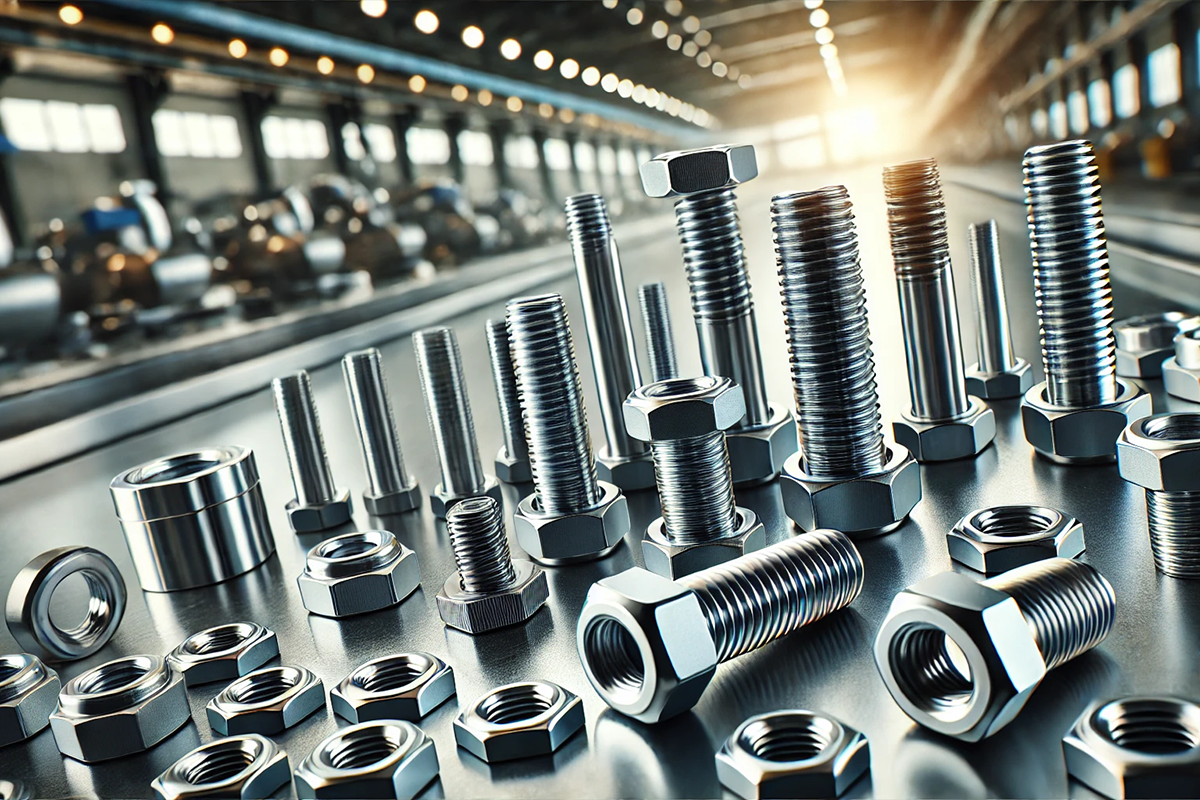

A roof screw is a specially designed fastener used to

secure metal, wood, or composite roof coverings to the structure. These screws

not only provide physical attachment but also help preserve insulation and

contribute to the overall safety of the building.

What Is the Function of a Roof Screw?

The function of a roof screw goes beyond simply

fastening a material. A correctly selected and properly applied roof screw

ensures the longevity of the roof. Properly installed screws support

waterproofing, prevent roofing materials from lifting in strong winds, and help

maintain thermal insulation. Especially in areas with high wind loads, the

strength of the screws directly affects the roof's integrity. Moreover, roof

screws make the installation process quicker and safer.

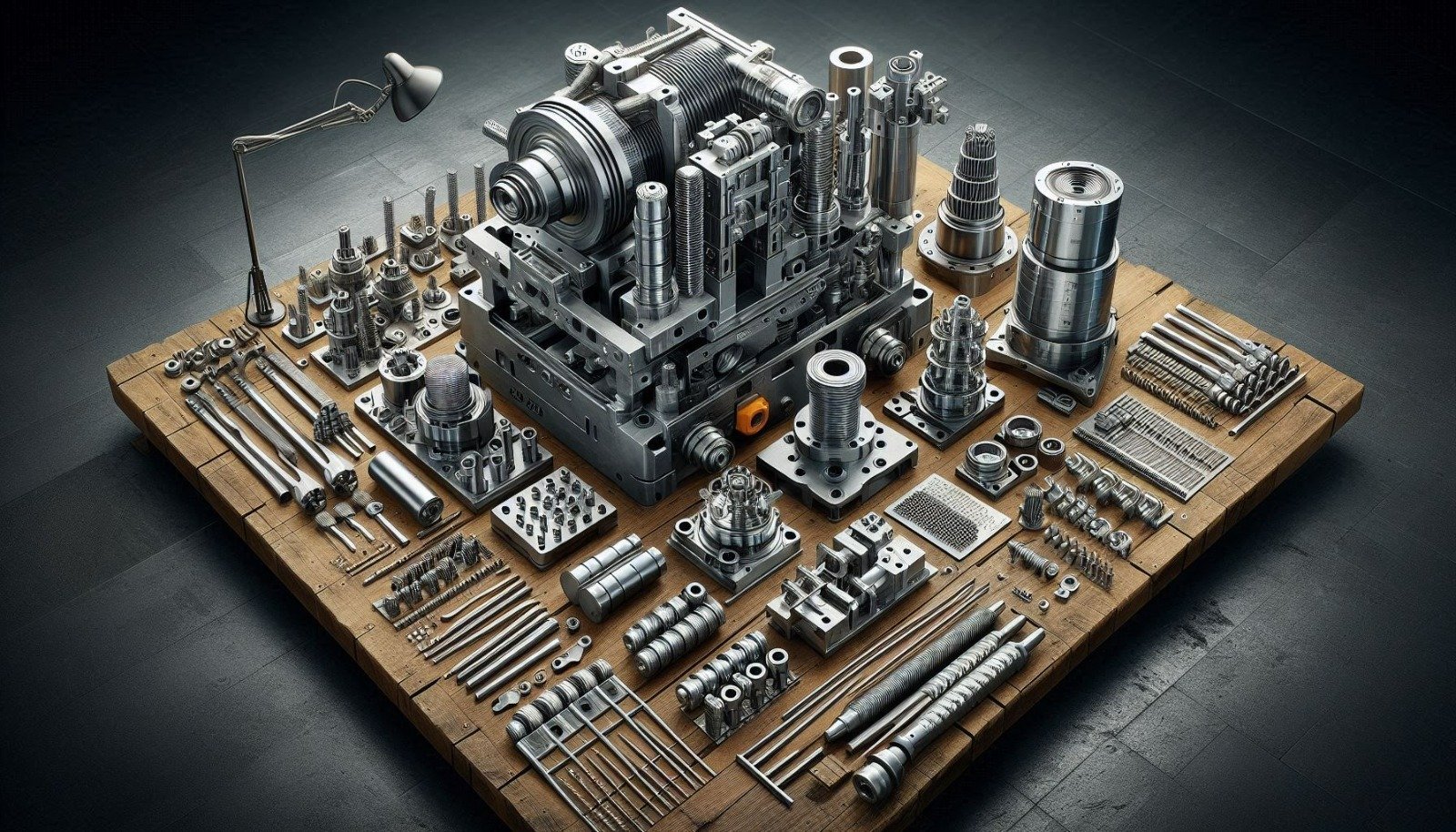

What Are the Roof Screw Types?

Today, many roof screw types are manufactured to suit

various roofing systems and applications. Each is designed to meet different

needs. Factors such as the type of material used, the mounting surface, and

environmental conditions play a role in selecting the right screw. Here are the

most commonly used types:

Trapezoidal Roof Screw

The trapezoidal roof screw gets its name from the

trapezoid-shaped metal panels. These screws are typically preferred in metal

roofing. Thanks to their specially sealed heads, trapezoidal screws provide

waterproofing and have high wind resistance. Often used in metal structures, they

offer advantages in durability and easy installation.

Wood Roof Screw

The wood roof screw is mainly used in wooden roof

structures under tiles, OSB boards, and wooden-covered roofs. This type of

screw is designed to avoid damaging the wooden structure. Its thread design,

head shape, and material allow for a tight grip without splitting the wood.

They are also available in galvanized or stainless steel options for long-term

use.

Self Drilling Roof Screw

A Self Drilling roof screw features a drill-like tip

that allows it to penetrate surfaces without the need for pre-drilling. This

saves time during installation. It is commonly used on metal surfaces and

reduces labor effort. Often favored in large-scale construction sites, this screw

type has become essential in industrial projects.

Stainless Roof Screw

As the name suggests, a stainless roof screw is made

of materials highly resistant to rust. This provides great advantage in coastal

areas, humid regions, or environments with chemical exposure. Preferred also

for aesthetic reasons due to their ability to maintain their appearance over

time, stainless screws are often found in high-budget structures.

Colored Head Screw

The colored head screw is chosen for both aesthetic

and functional reasons. Manufactured in the same color as the roofing material,

these screws are visually discreet. This ensures a seamless and elegant

appearance on the roof. Coated with UV-resistant paint, the color stays vibrant

and doesn’t fade easily.

How Durable Are Roof Screws?

Durability may be the most important criterion when

selecting roof screws. However, durability includes not just physical

strength but also corrosion resistance, sealing capacity, tolerance to

temperature changes, and long-term holding power. A high-quality roof screw

can maintain its function for over 10 years. Screws with sealing washers help

reinforce the roof’s most vulnerable points in terms of waterproofing.

Therefore, when choosing a product, it’s important to consider the

manufacturer’s reputation, coating technology, and the screw material.

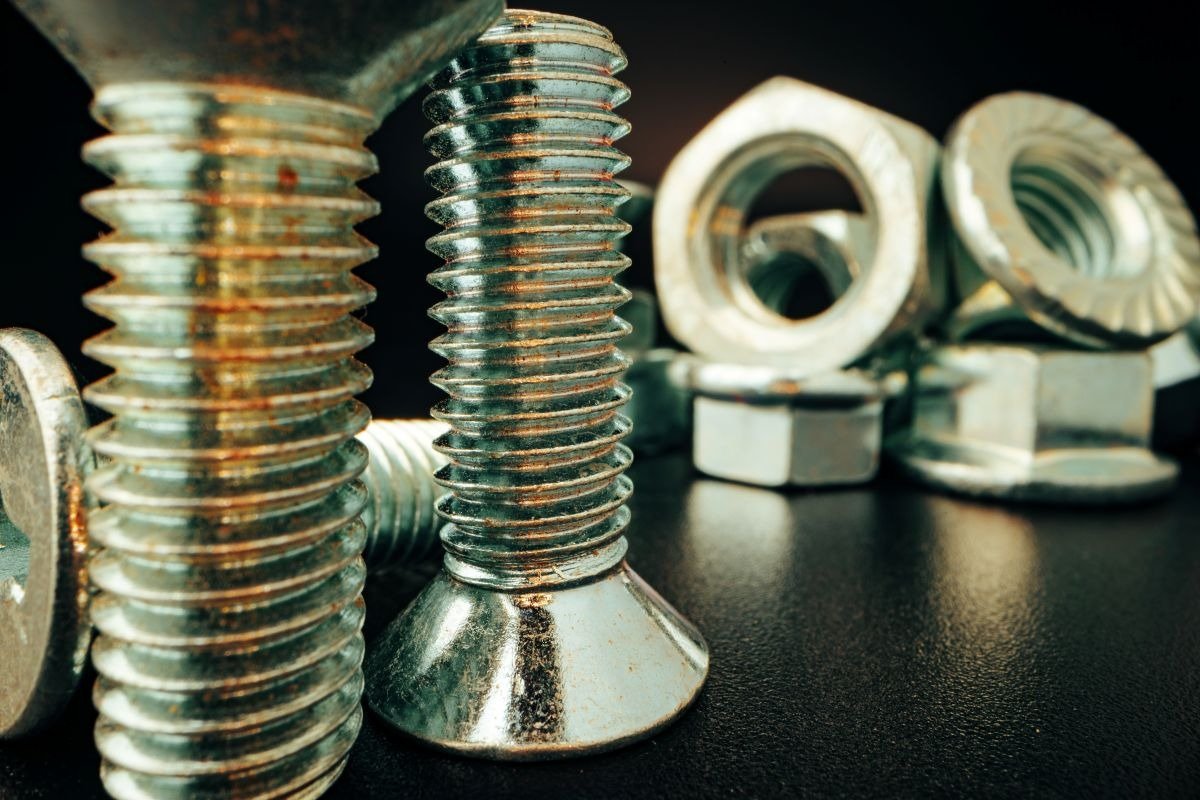

Things to Consider When Choosing a Roof Screw

A roof screw is more than just a screw—it's a key

component that defines the building’s lifespan. Several factors should be

considered during selection. First, the screw must be compatible with the

roofing material. Self Drilling roof screws are suitable for metal

roofs, while wood roof screws are ideal for wooden structures. Secondly,

consider the screw coating: galvanized, aluminum, or stainless options should

be selected based on environmental conditions. Third, do not overlook the

quality of the washer. Poor-quality washers can crack and cause leaks over

time. Lastly, aesthetic concerns should also be addressed, especially for

visible areas—colored head screws are the best option here.

What Equipment Is Needed for Roof Screw Installation?

For a roof screw to function properly, correct

installation is essential. Some tools are indispensable. First, a screwdriver

with adjustable torque is required. Over-tightening may damage the material,

while loose screws may lead to leaks. Proper bit selection is also vital to

avoid damaging the screw head. In some cases, pre-drilling may be necessary;

therefore, metal or wood drill bits should be included in the toolkit. Washers

compatible with insulation materials, special washers, and safety gear must

also be used to ensure a healthy installation process.

Anyone looking to build a quality roof system must pay

attention to these small yet critical details. The right screw means a solid

roof. And a solid roof means a long-lasting, safe, and comfortable building.