Bolt Production for the Automotive Industry: Which Types Are Preferred?

Bolt manufacturing plays a vital role in industries like

automotive, where high engineering standards and safety requirements are

paramount. The correct selection of each fastening component directly affects

the vehicle’s performance, durability, and safety. Therefore, bolt production

is not just a standard metalworking process; it is a specialized field of

manufacturing that requires high precision, engineering knowledge, and advanced

technology. Bolts produced for the automotive sector are not ordinary assembly

parts—they are critical components that ensure the integrity of the vehicle,

often invisible but indispensable.

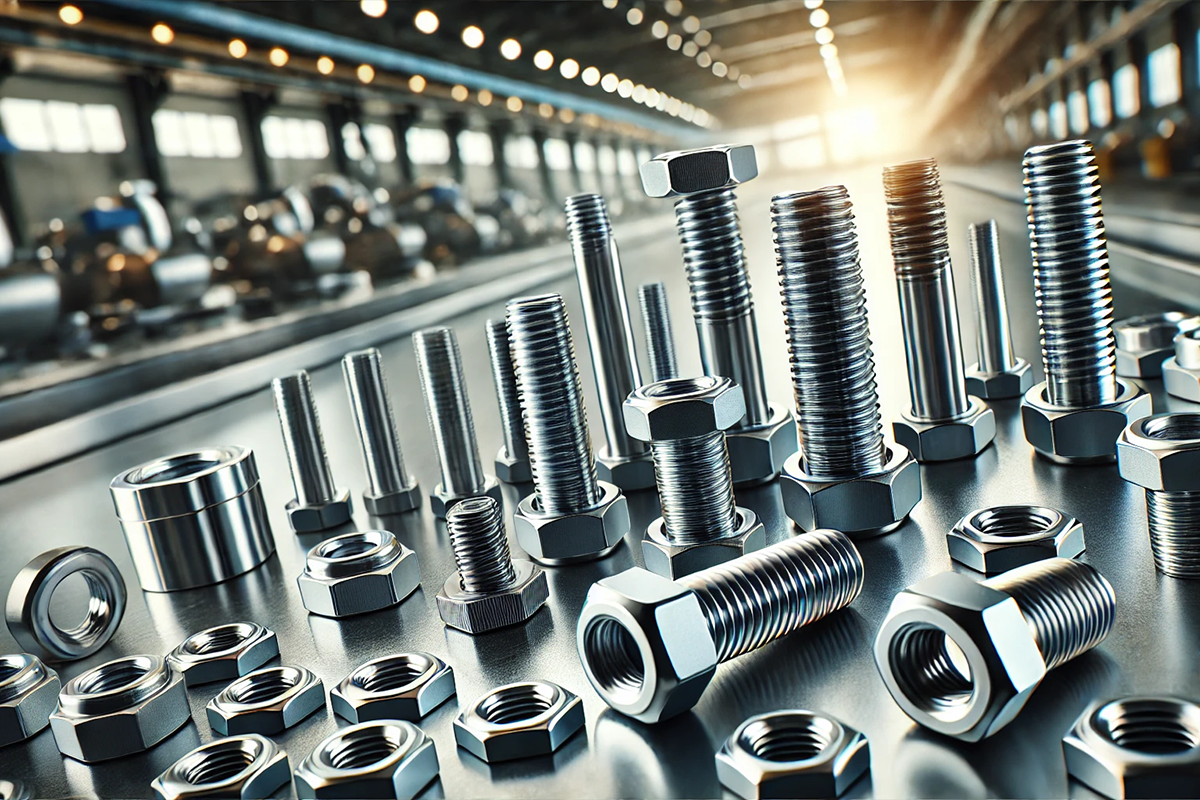

What Are the Types of Bolts?

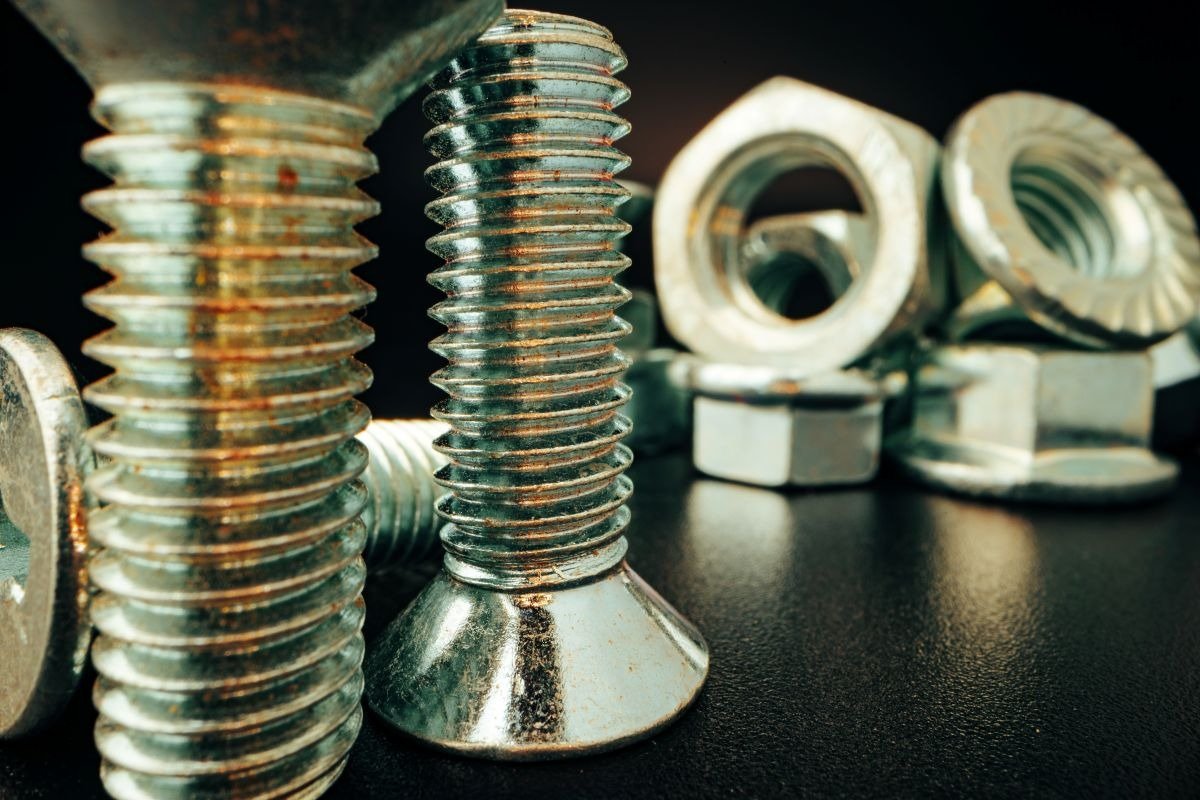

Bolts come in a wide variety based on their area of use.

Generally, they are classified according to head type, thread structure,

material, and type of coating. In the automotive industry, the most common

types of bolts include hex head bolts, flange bolts, socket head (Allen) bolts,

Torx head bolts, and specially shaped fasteners.

High-strength bolts are also preferred in areas of the

vehicle exposed to heavy loads, such as the engine, suspension, and braking

systems. In terms of material, carbon steel, alloy steels, stainless steel, and

in some specific areas, lightweight metals like aluminum or titanium are

commonly used. Additionally, surface coatings are of great importance—zinc

plating, phosphating, or special alloys are used to provide resistance against

corrosion.

What Is the Purpose of a Bolt?

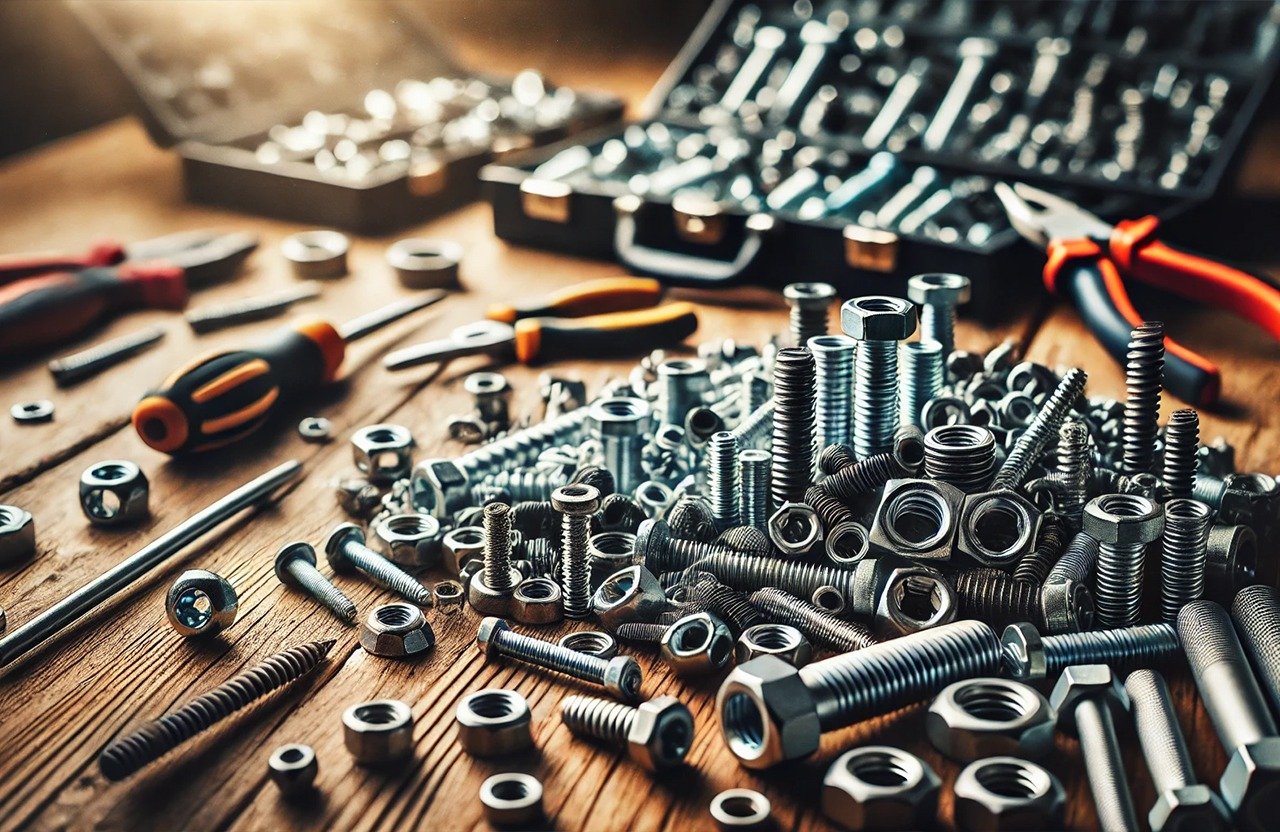

Bolts are used to connect two or more parts together. This

connection can be temporary or permanent. In the automotive industry,

detachable connections are generally preferred for servicing purposes, making

bolt and nut combinations common. The primary purpose of bolts is to ensure

that vehicle components remain assembled with the required order and tightness.

The size, thread structure, and material of the bolt are key to ensuring

resistance to the vehicle's vibration, temperature, and dynamic movements. Moreover,

bolts are not only used for fastening—they sometimes function as structural

support elements.

Why Are Bolts Important in the Automotive Industry?

Considering that a vehicle is made up of thousands of parts,

each component must be securely and reliably fastened. Bolts are the most

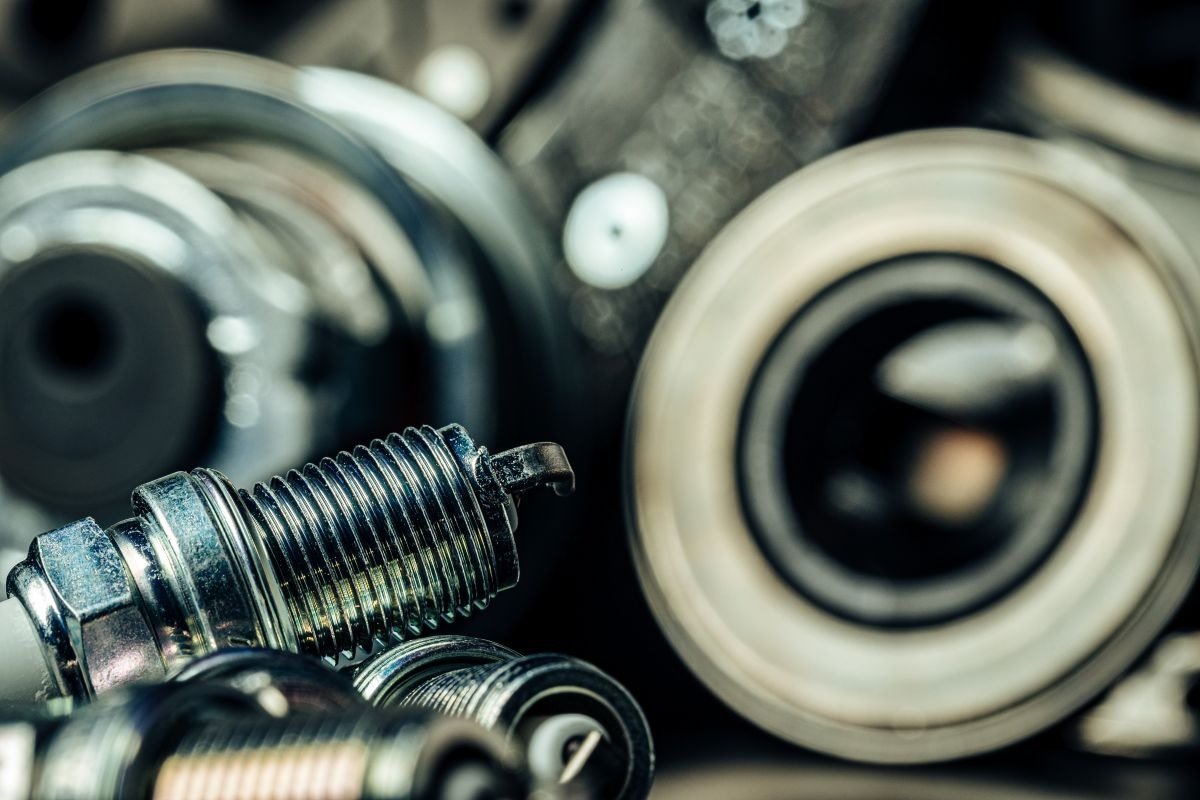

fundamental elements of these connections. From the engine block to the

chassis, from brake discs to the exhaust system, nearly every part is mounted

using bolts. Therefore, any connection failure can not only lead to performance

loss but also pose serious safety risks. Bolts used in the automotive industry

operate under both static and dynamic loads.

They are exposed to road conditions, temperature variations,

vibrations, and sudden impacts. This means that the materials and designs used

in bolt manufacturing must be suited to these harsh conditions. Additionally,

ease of assembly is a key consideration. In mass production lines, head shapes

and torque values that enable fast and error-free assembly are preferred.

How Are Bolts Manufactured for the Automotive Industry?

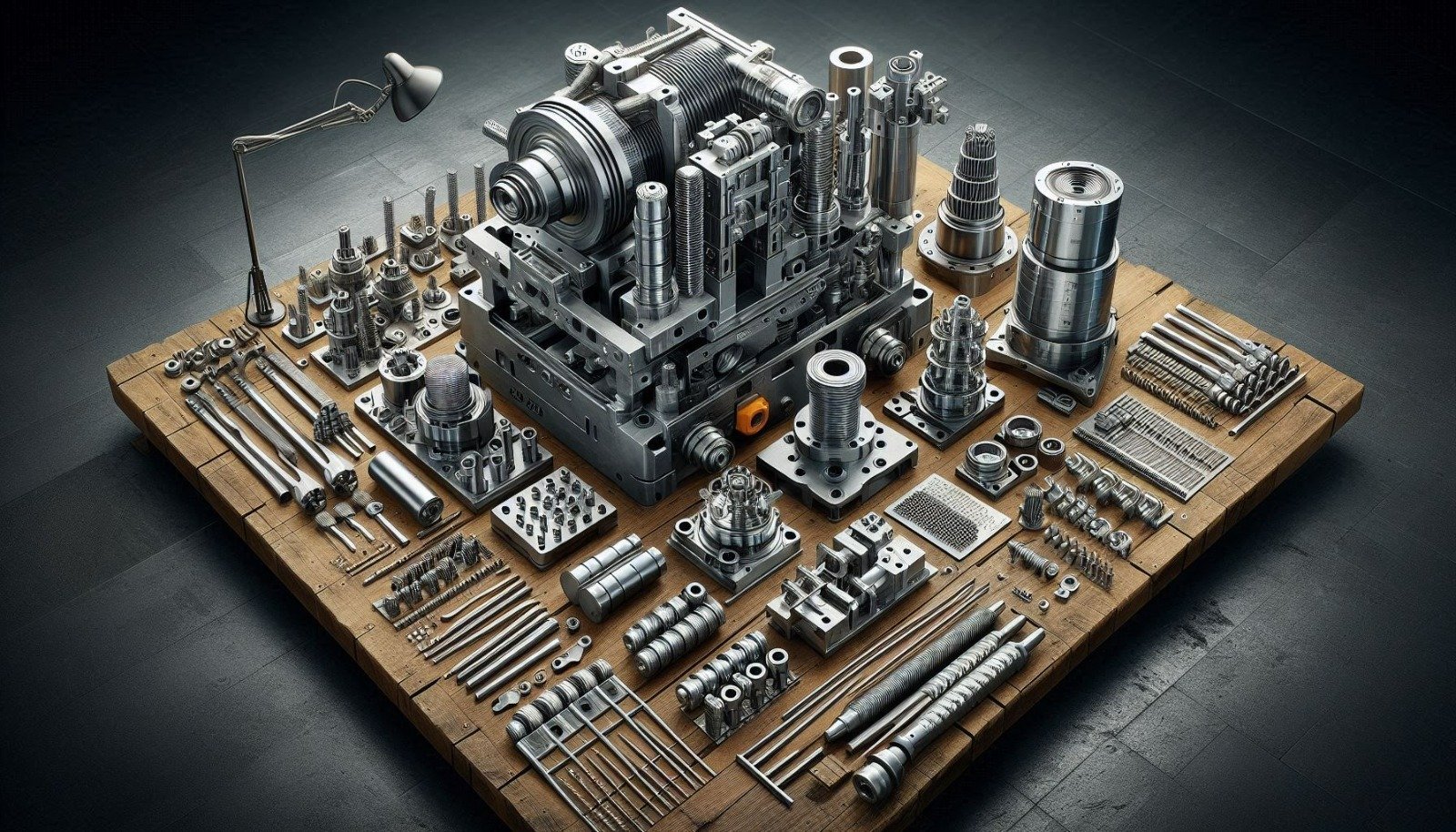

Bolt manufacturing for the automotive sector is a much more

complex process than producing ordinary screws. The first step is the selection

of appropriate materials—typically high-carbon or alloy steel rods are used.

These materials are shaped using hot or cold forging methods. After forming the

head and thread structure, heat treatment is applied to increase the bolt's

strength. This is one of the most critical steps, as it determines the bolt’s

durability.

Next comes the surface coating process. To improve corrosion

resistance and protect against external elements, bolts are coated with zinc,

nickel, or special alloys. In some special applications, coatings are also

designed to provide a lubricating effect to ease assembly.

In the final stage, quality control is carried out. For

bolts intended for the automotive industry, parameters such as torque value,

thread depth, hardness, and surface coating are meticulously tested. Compliance

with ISO and DIN standards is especially important. Some manufacturers even

integrate barcode systems to ensure traceability at every production stage.

This not only simplifies quality management but also allows the root cause of a

failure to be identified in the event of a defect.

How to Select Bolts for the Automotive Industry?

Automotive manufacturers select specific bolt types for each

connection point. Many criteria are considered in the selection process. First,

the load the connection will carry and the environmental conditions it will be

exposed to are identified. If there are challenging conditions such as high

temperature, intense vibration, or humidity, specially alloyed and coated bolts

are used. Additionally, certain head shapes are preferred to increase assembly

speed. For instance, Torx head bolts are more common on robotic assembly lines

due to their low slippage risk.

Torque value is also a key factor in the selection process.

Over-tightening or under-tightening can weaken the connection or cause damage.

That’s why each bolt has a specified torque range, and assembly equipment is

calibrated accordingly. Moreover, material compatibility is another important

consideration. Using a steel bolt on aluminum parts can lead to galvanic

corrosion over time. To avoid such issues, engineering teams consider both

mechanical and chemical compatibility.